|

Wings, Ailerons, Flaps

In the QuickBuild kit, the

wings, ailerons, and flaps are delivered nearly complete structurally.

The remaining tasks associated with completing them and fitting them to

each other will be documented here.

Specifications:

| Wings: |

|

| Airfoil: |

NACA 23013.5 (i.e. NACA

23000-series with thickness 13.5% of chord length) |

| Planform: |

Rectangular (excluding

swept composite tip) |

| Twist, a.k.a washout: |

0° |

| Chord length: |

58.25 inch |

| Panel span, root to tip: |

109.5 inch (one wing

panel, excluding wing root fairing and composite wing tip) |

| Total span, tip to tip: |

300 inch (including

composite wing tips, fuselage, etc.) |

| Total wing area: |

121 ft² (total span ×

chord length) |

| Total aspect ratio: |

5.15 (total span / chord

length) |

| |

|

| Ailerons: |

|

| Type: |

Frise, with differential

deflection |

| Up deflection limit: |

+27° to +32° |

| Down deflection limit: |

-15° to -17° |

| |

|

| Flaps: |

|

| Type: |

Plain |

| Up deflection limit: |

0° |

| Down deflection limit: |

-40° |

Running Total Hours:

0.0

| 2006.03.18:

(2.0) Started preparing

(edge-finishing, etc.) parts for the the aileron attach brackets. |

| 2006.03.19:

(1.5) Done edge finishing the

aileron attach brackets. |

| 2006.03.21:

(1.0) Applied corrosion

protection (AKZO) to the aileron attach bracket parts. |

| 2006.03.22:

(1.0) Riveted the aileron

attach brackets.

|

| 2006.04.xx:

(2.0) Edge-finished the

aileron gap fairings. |

| 2006.04.10:

(1.0) Match-drilled the

aileron attach brackets to the wings. Had to do some more

trimming so that they would nest in the radius of the rear spar flange

and sit flat on the spar web. So... I have to wait until I can

touch up the primer in the trimmed area before installing them. |

| 2006.04.13:

(1.5) Started trimming and

edge finishing the flap braces. |

| 2006.04.19:

(1.0) Done trimming and

edge finishing the flap braces. |

| 2006.04.22:

(3.0) Sprayed AKZO on on the flap

braces, aileron gap fairings, inspection hole cover plates, and the

areas I had to trim on the aileron attach brackets. |

| 2006.04.23:

(1.0) Started installing the aileron

attach brackets to the wing. Got as far as I could reach with

the squeezer. |

| 2006.04.29:

(0.5) Finished riveting the aileron

attach brackets to the wing. Used the squeezer with a 4"

yoke and a 5/8" tall flat set, effectively creating a longeron

yoke with a 4" reach. I bought the 5/8" tall flat set

from Avery. |

| 2006.04.30:

(1.5) Match-drilled the A-406-1 and

A-407 brackets to the ailerons. |

| 2006.05.03:

(0.5) Tapped the tie-down blocks to

3/8-16 coarse thread for the Van's tie-down rings. |

| 2009.05.28:

(0.0) Finally got back to the wings

a couple of weeks ago. Here's a summary:

Trimmed the inboard ends of the aft spars per DWG 38. Rough cuts

with a die grinder, just a little bit at a time to keep heat buildup

in check, then finish with a file. Some builders report an

interference between the inboard end of the aft spar and a domed rivet

just above the attach point on the fuselage, necessitating either

additional trimming of the spar or replacement of the rivet with a

flush head Cherry Max. I'm holding off on this for now.

Installed the aileron gap fairings. An issue came up, where the

top skins needed to be bent downwards slightly into position.

Not a problem where the aileron gap fairing will hold them in place

with minimal tension. But there's a section of the outboard top

skin that extends inboard of the ailerons and is therefore not

supported by the aileron gap fairing, so it needed to be pre-bent by

hand so that it will match the contour of the supported area.

Did this carefully with good results. Also, the aileron gap

fairings needed to be trimmed slightly to clear some interference with

the aileron hinge brackets.

Fitted the ailerons to the wing. Installed the A-406 and 407

brackets to the ailerons, and mated them to the wings. DWG 13A

shows the spacers (washers and aluminum tubing) around the bearings

that set the spanwise position of the ailerons, noting that these

spacers may have to be adjusted for "proper fit".

Indeed, the spacers as called out didn't quite add up on my

wings/ailerons. I called up Van's to make sure I knew what

constrains this "proper fit", if there are any critical

dimensions. They assured me that this wasn't critical

aerodynamically, and that I just had to make sure that there is

adequate clearance, nominally 1/4", minimum 3/16", between

the aileron and the flap and between the aileron and the wing

tip. They suggested that I initially set my spacers for the

middle of the range of adjustment that I have, so that I can later

tweak it slightly in either direction to even out the clearances to

the flap and wingtip. Sounds good to me. So, using the

outboard bearing as reference, my range of adjustment is as

follows. Most inboard aileron position: three standard washers

outboard of the bearing, one standard washer inboard of the

bearing. Most outboard aileron position: two standard washers

outboard of the bearing, two standard washers inboard of the

bearing. Center and initial aileron position: two standard

washers and one thin washer outboard of the bearing, one standard

washer and one thin washer inboard of the bearing. Until I have

the flaps and wing tips fitted, I'll hold off on making the aluminum

spacers for the inboard aileron bearings. CORRECTION 2009.09.14:

The stackups of washers listed above are too wide. The aileron

bracket sits more squarely with one thin washer less. The two

possible stackups are therefore two standard washers outboard and one

standard plus one thin washer inboard, or two standard and one thin

outboard and one standard only inboard.

Rigged the ailerons to the bellcranks. Firstly, I noticed that

DWG 15A specified a dimension of 2-7/16" from the aft face of the

spar web to the center of the bolt on the bellcrank, while the actual

W-730 bellcrank jig used to set this dimention actually measured

2-3/8". Slight discrepancy, but I called Van's to clear

this up. They instructed me to use the W-730 jig and not worry

about the plans. Ok... Moving on, I made a simple jig to

set the neutral position of the ailerons themselves. The neutral

position is specified as the trailing edge of the aileron being

in-line with the two tooling holes in the aft wing rib. I used a

piece of Al angle and a couple of 3/16" AN bolts that slide

through it and into the tooling holes, and marked a line extending

through the centers of both bolts. Simple and effective.

One aileron at a time, I held the bellcrank in its neutral position

using the W-730 bellcrank jig, and adjusted the pushrod end bearings

until the aileron was also in its neutral position. Note that

these are the skinny pushrods from the bellcrank to the aileron.

The fat pushrods that go the fuselage haven't entered the equation

yet. Note also that I have not yet made the spacers for the

pushrod attachment to the aileron. I'll hold off on these until

the flaps and wing tips are fitted, and I've determined the final

span-wise position of the ailerons.

Now I'm starting fit the various sensors and actuators that will go in

the wing, so that I can finally close out the outboard bottom

skins. These will include the pitot

probe, AoA ports, OAT probes, autopilot

aileron servo, and landing lights. Wiring runs will also

have to be provided for the strobes, nav lights, and antennas that

will be installed in the wing tips. |

| 2009.09.09:

(0.0) Update on various tasks in

the wings:

I created some drawings (in OpenOffice Draw) to plan the layout of the

various sensors, actuators, wiring, and plumbing runs in the

wings. Also created a spreadsheet (in OpenOffice Calc) to select

appropriate wire gauges for the wiring runs. I'll put these up

on the web page soon.

Installation/fitting of the various sensors and actuators is coming

along nicely. These are documented in their respective pages.

Holes for wiring

Started making accomodations for the physical wiring runs. I

considered several options, including those suggested by Van's in this

note. I ultimately decided to add a hole in the ribs as

shown in option 2, but use snap bushings rather than conduit [I don't

see that conduit would add much utility in this case, and it presents

potential problems with chafing as the wires enter/exit the

conduit]. My plan is to select snap bushings that are just

slightly bigger in diameter than the wiring harness at every point in

the wing. I don't have all the needed varieties of wire and

cable yet to get these measurements, but I can make some rough

guesses. On the inboard section of the wing (wing root to

aileron bellcrank) 1/2" diameter or less should suffice, and on

the outboard section of the wing (aileron bellcrank to wing tip)

3/8" diameter or less should suffice. I therefore drilled

the holes in the inboard section to 5/8", which can accomodate

snap bushings with inner diameters up to 0.500", and drilled the

holes in the outboard section to 1/2", which can accomodate snap

bushings with inner diameters up to 0.391". Snap bushings

with smaller inner diameters are also available for these outer

diameters. See chart

of available Heyco snap bushings.

Drilling these holes is another instance of a task that could have

been performed very easily before the wing was assembled, but was a

lot more tricky on a pre-assembled QB wing, especially on the inboard

section where there are several closely spaced ribs and the bottom

skin is already on. I first used a properly scaled printout of

the drawing in

Van's note to locate and pilot-drill all the holes. It

ultimately took many steps, some yoga-like body contortions, an angle

drill adapter, drill extensions, standard drill bits, extra-long drill

bits, and unibits to enlarge the holes to their final size. What

finally made the job possible (and would have made it just a bit

simpler if I had it a couple of days sooner) was a 12" drill

extension for 3/8" shaft diameter bits (Irwin #3 unibit) that

could fit through a 5/8" hole. To my surprise I couldn't

find such a thing. But I did find one that had a 3/4" max

outer diameter, and my buddy Buzz was kind enough to have one his

buddies machine it down for me on a lathe to 9/16" outer

diameter. The original tool was a Ridgid 12" Hole Saw

Extension, p/n 7035. It was about $10 at the aerospace isle at

Home Depot. Note that Home Depot also had extensions for

1/4" shaft diameter with about 9/16" max outer diameter, and

perhaps this could have been bored out to 3/8" inner

diameter. Just another option.

OUTBOARD BOTTOM SKINS:

Working toward getting the outboard bottom skins ready to close.

Firstly, I had a lot of work to do on the rib flanges. This is

yet another instance where doing the job right prior to wing

assembly would have been a lot easier. Unfortunately, the QB

factory did flute the rib flanges, but seemingly without any

particular objective in mind. The rib flanges were far from

square to the rib webs, and the rib webs (and more importantly the

flange rivet lines) were far from straight. I took several hours

to get these into shape.

Secondly, a few of the small rib flanges that meet the main and aft

spars are somewhat mis-shapen and create a gap between themselves and

the spar. In most cases the gap is sufficiently small that it

should pull together when riveted. But on the outboard rib of

the left wing, the gap to the rear spar is substantial. I made a

shim from 0.032" aluminum to fill the gap.

Now to the skins themselves. I decided to dress the edges and

prime the inside surfaces before match-drilling the holes. When

I removed the blue protective plastic from the left wing skin I had an

unpleasant surprise: the beginning of filliform corrosion was evident

in several areas along the edges. I had heard that in some cases

leaving the blue plastic on there during long term storage can

actually promote corrosion, not sure exactly how/why. And I

haven't seen this happen with any other parts. Anyway...

After dressing the edges, I used scotch brite pads to abrade away the

corroded areas down to clean metal, then gave them a swipe with the

alodine pen. I then cleaned and abraded the entire inside

surfaces of the skins and shot AKZO primer on them. |

| 2009.09.14:

(0.0) Clecoed the outboard bottom

skin to the left wing and match-reamed the rivet holes to final size

(#40), except for holes that are already dimpled or countersunk on the

wing (1. the main spar, and 2. the skin overlap) which I will ream to

final size in isolation.

Also took the opportunity to fit the flap. First I fit the flap

brace. I had already dressed the edges and primed it a long time

ago, but clecoing it on it became apparent that some massaging will be

necessary to get a good fit. The angles of the flanges are

pretty much dead on for the main portion of the flap brace, but the

short sections at the ends didn't sit quite right because of the

different angle that they attach to the rear spar over the

doublers. Clecoing everything into position would put tension on

the structure and distort the skin. So I clamped the flap brace

to the work bench and carefully adjusted the flange angles. It

only took two iterations of eyeball and trial and error to get it just

about perfect. Now everything can be buttoned up with no stress

and no deformation.

Now to the flap. The flaps themselves were actually completely

assembled at the QB factory, so fitting them to the wings simply means

setting the exact location in attaching the (half) hinge to the wing

side. The span-wise position of the flap is set in reference to

the aileron, so I installed the aileron at what I now consider its

nominal position, with two standard washers and one thin washer on the

outboard side of the outboard aileron hinge. The flap is then

positioned such that there is nominally 1/4 inch (minimum 3/16 inch)

clearance between the outboard edge of the flap and the inboard edge

of the aileron. I set mine to 1/4". The chord-wise

position of the flap is set so that nominally its trailing edge

matches the trailing edge of the aileron while in the neutral

position. Some builders have reported problems with this,

stating that a wider hinge had to be used to set it sufficiently aft

without violating the edge clearance requirements. I didn't find

any such problems. The holes ended up smack dab on their nominal

location on the hinge, with edge clearance to spare, and the trailing

edges are dead on. Maybe it was a problem early on and Van's

later fixed it, or maybe I just got lucky. Anyway, all went

well.

|

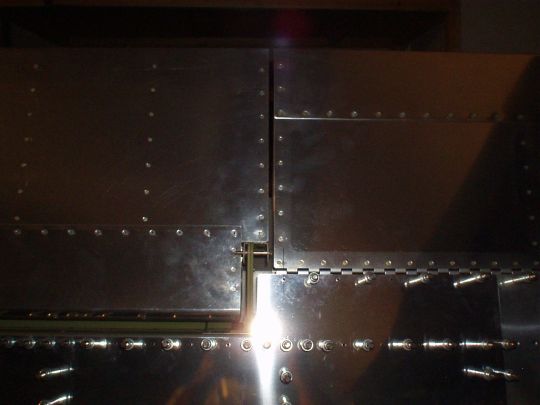

| 2009.11.01:

(0.0) Flap hinge pins: There are

basicall two options for insertion and removal of the flap hinge

pins. 1) Drill a hole through the inboard aileron hinge bracket

so that the flap hinge pin can slide through it, or 2) Remove three

hinge eyelets (one from the wing and two from the flap) in the middle,

and slide in a half-length hinge pin in each direction through the

gap. I chose the latter, and built in a neat arrangement for

securing the hinge pins. A picture is worth 1000 words:

And... I finally riveted the flap braces to the aft wing spar.

By doing this before riveting on the bottom skin, I was able to at

least use solid rivets at the outboard end where the wing bay is still

open. (I also used a solid rivet at the most inboard end).

Now riveting flap brace to the skin and hinge will have to wait until

the outboard bottom skin is riveted on, which will hopefully be very

soon. |

| 2010.01.22:

(0.0) Closed the right wing,

i.e. riveted on the outboard bottom skin. Did this over several

sessions totalling about 8 hours. A big thanks to my riveting

partners: my good friend and flying partner Jimmy for the three

inboard bays, and fellow RV builder John Francis for the three

outboard bays.

In closing out this skin I took a slightly different approach from

Van's normal method. Van's method as described in the manual is

to start with the inboard aft corner, peeling the rest of the skin

away to provide bucking access, and working out toward the outboard

forward corner half a bay at a time. This is fine access-wise,

but what I didn't like about it was the potential for warping and

wrinkling due to uneven distribution of tension in the skin, a fairly

common problem seen on many RVs. My preferred approach was to do

as much riveting as possible with as much of the skin as possible

clecoed (or already riveted) in its proper position on the wing with

any stresses evenly distributed. I still worked generally from

the inboard end toward the outboard end, but with the skin fully

clecoed on the wing most of the time. Following is a summary of

the sequence is used:

1. Cleco the entire skin to wing, taking care to line it up as well as

possible and distribute its tension as evenly as possible.

2. Rivet the three inboard bays while the skin is fully clecoed.

Every rivet in the three inboard bays can be bucked through the access

hatches. [Note that I started by putting in a few rivets along

the main and aft spars in these three bays to "tack down"

the exact position of the skin so it can't creep or shift around in

one direction or another. Only then I filled in the remaining

rivets inbetween, again in such a distributed order such as to not

induce creeping. I use this technique throughout.]

3. Un-cleco the skin from the outboard-most two bays of the wing, as

well as the main spar of the next bay.

4. Rivet the next bay, which has to be done basically by Van's method,

with the skin peeled back from the bays further outboard.

There's just no other access to bucking those rivets. [It would

sure be nice if there was one more access hatch! Then the whole

wing could be done without peeling back the skin!] Here too, I

started by putting in a rivet near the outboard end of that bay along

the aft spar to tack down the geometry. Then filled in the

remaining rivets along the aft spar and along about the aft half of

the rib. I then clecoed along the main spar and riveted the main

spar and the remaining forward half of the rib.

5. Re-clecoed the skin to the entire remaining section of the wing.

6. Rivet the remaining two bays (the outboard-most two bays) while the

skin is fully clecoed. These can be bucked through the oubtoard

end of the wing.

The results look great. The skins look smooth and the tension

feels right and is well matched across all wing bays. I should

have a straight wing.

WORD OF CAUTION: Some serious "yoga" is needed to buck a few

of the rivets using this approach. And I have long skinny

arms. Some folks will surely not be able to do this.

Before committing to it, I did a dry run just to be sure I could reach

all the rivets this way. I strongly suggest that anyone

considering this approach should first do such a dry run themselves. |

| 2010.01.22:

(0.0) Finished closing the left

wing, again over several riveting sessions with help from John F. and

Jimmy. |

|

|