|

Stick Grips

Running Total Hours:

0.0

| 2008.03.15:

(0.0) I selected the

military-style stick grips made by Infinity Aerospace. The

design of these grips is closely modeled after those found in many 3rd

generation American jet fighters, such as the F-4 Phantom II.

They are contoured to fit the shape of the hand, and have a number of

switches strategically mounted for easy access right on the

grip. The idea is that the pilot can access various functions

without having to look down into the cockpit or fumble to reach for

switches on the instrument panel. The military term for this

concept is HOTAS: Hands On Throttle And Stick. Makes good

sense. The main differences between the Infinity grips and their

military cousins are:

1. The Infinity grips are scaled down slightly compared to the

military grips, to be more comfortable for an average human's hand,

and not wearing gloves.

2. The Infinity grips are available in a right-handed version (like

the military grips) and also a left-handed version that's a mirror

image. The left-handed grip is better suited for the left seat

of a side-by-side airplane with a center throttle, like the

RV-7A. Mine will have a lefty on the left and a righty on the

right.

3. The Infinity grips, while certainly not cheap (about $175 each),

are a lot cheaper than the genuine military grips. They also use

standard switches in commonly available form factors instead of exotic

and expensive mil-spec varieties.

Infinity Aerospace, incidentally, is a local company based at

Gillespie Field. And the man behind the company is J.D. Newman,

a retired U.S. Navy F-14 pilot. When I came by his hangar to

pick up my grips, he showed me his own airplane project, retractable

landing gear hardware that he designs and sells, and other projects he

has in the works. Cool stuff!

|

| 2008.04.10:

(0.0) Started fitting

the grips to my stick tubes.

First it should be noted that the left and right sticks on the RV-7A

are not the same. The left hand stick is a single welded

assembly that is non-removable, with a stick tube that is 1"

outer diameter, and approx 0.035" wall thickness

(measured). The right hand stick is in two pieces: a base and a

removable stick tube. The stick tube itself is 7/8" outer diameter,

and apporx 0.050" wall thickness (measured). The Infinity

grips are designed to fit over a 1" diameter tube, so the left

stick is good as is. For the right stick, I bought a spacer that

Infinity sells for exactly this purpose.

Stick length in the RV's is a contentious issue. In RV-6 and -8

series aircraft, there are interference issues between the sticks and

the panel and/or other structures in the cockpit, and therefore

builders are often forced to shorten the sticks to remove the

interference. In the RV-7 series there is no interference

issue. Still, many -7 pilots report that they prefer the control

feel and ergonomics of a shorter stick to the stock length.

Van's strongly discourages this practice (see articles in the

RV'ator), noting the effects on control sensitivity and stick

forces. I decided to act conservatively and keep essentially the stock

length. I can always slide my hand down the stick below the grip,

as some do, at appropriate phases of flight. And if at a later date I do

decide to shorten the sticks, that's always an option.

Having said all that, I did have to shorten the stick tubes in order

to keep the same effective stick length once the grips are

mounted. The Infinity grips are designed to slip over only

2.125" of the tube, and there is another approximately

2.875" from there to the top of the hand in its natural

position. I decided somewhat arbitrarily that the natural hand

position on the bare stick tube would be with the top of the hand at

0.5" below the top of the tube. So to maintain the

equivalent hand position with the grips, I had to shorten the tubes by

3.375". Note also that the left and right stick tubes

weren't exactly the same length to begin with (other builders have

reported the same). The left stick was about 0.5" longer

than the right stick. This difference isn't meaningful, but

rather just falls within Van's generally loose design and

manufacturing tolerances. Anyway, I took the average of the two

as the nominal length, and so I trimmed the left stick tube by 3.625"

and the right stick tube by 3.125" to achieve approximately the same

nominal stick length on both sides.

The top of the stick tube then needs to have two 29/64" holes on

the left and right sides, 0.5" from the top, to receive a lug on

the inside of the grip that keeps it from rotating or sliding up the

tube. And a 0.5" wide notch on the aft side, from the top

down 1.25", to provide a channel for the 17-conductor

cable. But per J.D.'s advice, and that of other builders, the

ideal orientation of the grip is not at right angles, but rather rotated somewhat so that it is more in line with the forearm.

This way, there is less or no bending in the wrist (at least in the

neutral position), making it more comfortable. I'll want to just

sit in the airplane and play with it to find the most comfortable

angle for me. So for now I've only cut the holes and notch

in the right side stick tube, which is free to rotate until I drill

the hole for the bolt that secures it to the bottom piece. I'll

use the right side stick to do this because with

the left hand stick, being non-removable, there is no such

freedom.

|

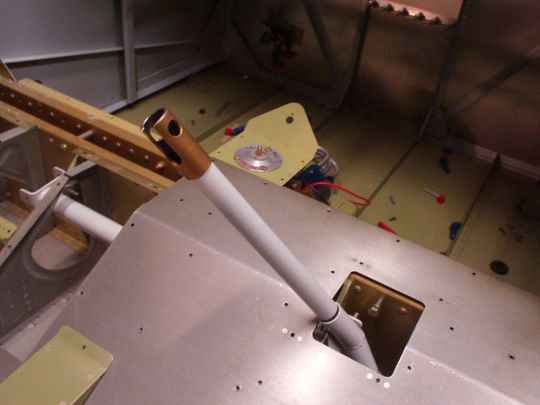

| 2008.04.14:

(0.0) Stick grip

orientation.

I installed the right side stick in the airplane, installed the seat

floors, and dropped in a makeshift seat cushion (a folded up furniture

blanket). I set a ladder next to the airplane and -- for the

first time ever -- climbed into the cockpit. Playing with the

stick a little bit (and really enjoying it!) I found that 1) indeed it

is uncomfotable with the grip oriented straight ahead, and 2) the most

comfortable orientation for me was with the grip rotated about 22.5°

counter-clock-wise, putting it more-or-less inline with my forearm.

Armed with this information I went ahead and cut the notch and

mounting holes in the left hand stick, orienting the grip at 22.5°

clock-wise. I also then drilled the bolt hole that secures the

right side stick tube (F-669) to the base (WD-611), orienting the

right side stick at 22.5° counter-clock-wise.

Note that the bolt securing the right side stick tube to the base is

not in the original plans. It is specified in Van's service

bulletin SB 07-2-6, which was issued as a result of -- you guessed it

-- an accident caused by the stick tube popping out of its base during

a landing. Now, one might say having some means of securing the

stick to its base would seem like common sense. I for one would

agree. But apparently it didn't occur to Van's, and to at least

one builder [and probably many more], until the inevitable actually

occurred. This example illustrates why I will continue to fix

potential problems as I find them, despite Van's and many in the

builders' community insisting that "it's never been a problem for

me, so

don't worry about it."

|

| 2008.09.01:

(0.0) I started

examining my options for routing the cables from the sticks toward the

panel, and quickly realized that this will not be a trivial

task. The problem is that the cable is so thick and inflexible

that it is almost impossible to have it transition from the stick to

an unmoving part of the airframe without it either putting noticeable

forces on the stick, or having excessive free-floating cable that

would chafe or potentially interfere with other moving parts

associated with the flight controls.

I experimented with various ideas by zip-tying a length of cable to

the stick and playing with the cable routing. The most promising

approach was actually to have the cable exit the stick on the forward

side, part way up, and be secured with zip ties down the stick until

it becomes free near the axis of rotation, but oriented straight

down. From there it loops around and is then secured to the

torque tube, following it inboard. Then, it makes another

transition from the torque tube to an unmoving part of the

airframe. The advantage of this approach is that instead of

making one transition with two axes of freedom, it makes two separate

transitions each with only one axis of freedom. Each is

therefore geometrically simpler, can be accomplished in smaller space,

and can more easily be accomplished without imposing noticeable forces

on the stick. The disadvanted however is that this routes the

cables right through the heart of the flight controls area, and if the

cable came loose somehow (zip ties break, etc.) it could potentially

jam up the controls.

As an alternative, I am now considering puting active electronics in

the stick tube itself to scan the switches and transmit serial data

back to the panel. That would relieve me from having to route

that humangous cable around the cockpit, and instead I'll only have to

deal with a much smaller and more flexible 3-conductor cable (power,

ground, serial data) instead. It also relieves me from having to

drill a very big exit hole for the cable in the wall of the tube,

which makes me somewhat uneasy, structurally speaking. We'll see, I'll put this aside for

now. |

| 2009.03.03:

(0.0) Lots of

activity over the last few weeks, but I'll just summarize. I

decided to go with the serializer idea, and I've got it built. I

won't go into too much technical detail here, but basically I designed

and built a serializer board as I described previously. It scans

the switches and transmits their state over RS-232 at a rate of appox

300 samples/s. The physical dimensions of the board are approx

4" L × 0.75" W, and I enclosed the whole thing in

heat-shrink tubing for added protection. It nestles nicely

inside the stick tubes.

Out the bottom comes a 3-conductor 24

AWG shielded cable to a 4-pin M8-size AMP/Tyco Miniature Circular

Plastic Connector ("Miniature CPC"), making the stick easily

removable from the fuselage. The pinout of the connector is as

follows:

| Connector pin |

Cable conductor |

Board J2 pin |

Description |

| 1 |

1 (white) |

1 |

Power (operating voltage +4V to

+60V) |

| 2 |

2 (white/blue) |

2 |

Serial data (RS-232) |

| 3 |

3 (white/orange) |

3 |

Ground |

| 4 |

shield |

n/a |

Shield (should be grounded at main

board) |

Ultimately the stickgrip

serializer cables will connect to a main board in the forward cockpit

that will receive the switch states as well as other airframe sensor

inputs, and will control the various airframe actuators: flaps, trim,

fuel pump, lighting, and interface to avionics. For now, I just

made a little adapter cable and test program so I can plug the

stick grips into a PC to test them. All looks good.

Just a few details about the board design process:

CAD Tools: I used the open source gEDA tool suite on Linux to create

the schematics and board layout. This is the first time I've

used the gEDA package, and I found it to be a mixed bag.

Compared to the commercially available tools I've used before (OrCAD,

Pads, etc.), the gEDA tools are definitely less user-friendly and more

rough around the edges. But after a bit of a steep learning

curve, I actually found them quite useable, at least for a simple

design like this. One big upside to the gEDA tools is that their

design files are all just formatted ASCII. This facilitates

creation of my own helper scripts, which I did, and also makes it

possible to diff two versions of a design file. I'm a big

proponent of that!

Board FAB: I used www.4pcb.com to

fab the boards. Good prices at prototype quantities, good

manufacturing quality, automated DFM checker for gerbers uploaded to

their website, and a quick turnaround, delivered as promised.

This was my first time using them, and I would use them again.

Board assembly: Did this myself. I currently don't have easy

access to professional assembly/rework lab, so I set up a basic lab at

home. No microscope... but thankfully I have good eye sight and

was able to solder the fine-pitched parts without too much difficulty.

|

| 2008.04.16:

(0.0) Fitted the

stick grips into the fuselage, which meant mounting a mating connector

into the seat ribs and then adjusting the stick grip's cable to

provide the desireable routing and freedom of motion. I then

zip-tied the cable to holes I had drilled in the stick to provide

strain relief and hold the cable at the correct position.

|

|

|