|

Fuel System

Running Total Hours:

0.0

| 2006.05.23:

(0.0) Since I'm planning on

a fuel-injected engine, I'll need a high-pressure (25 psi) auxiliary

fuel pump, rather than the standard low-pressure pump used for carbureted

engines. I'm using Van's kit "7/7A F.I. PUMP INSTAL",

which includes an Airflow Performance p/n 3090050 boost pump package,

an Airflow Performance p/n 1090079 fuel filter, and various parts for

installation in the cockpit. The Airflow Performance 3090050

boost pump package consists of the following pre-assembled components:

p/n W-7135X pump motor, a 25 psi relief valve, a swing check valve for

bypass, and a manifold, fuel line, and fittings that put it all

together.

Unlike the standard low-pressure pump which mounts on the firewall,

the high-pressure pump mounts on the cockpit floor under the fuel

selector. This requires modifications to the cockpit structure in the

area of the fuel selector. See section Cockpit

Floors and Covers, entries starting with 2006.05.23. |

| 2006.07.08:

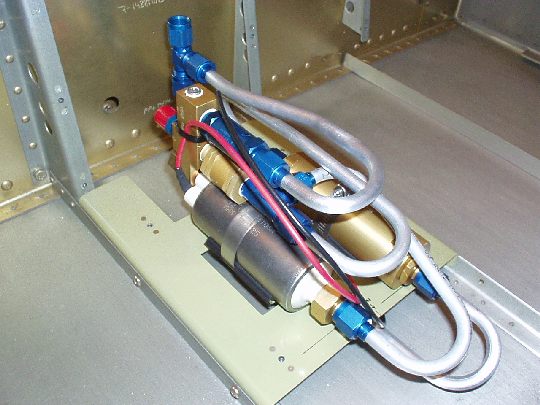

(1.0) Mounted the electric

fuel pump and fuel filter on the bottom cover plate. |

| 2006.07.14:

(3.0) Practicing and experimenting

working with the 3/8" aluminum tubing and tubing tools.

Measured that 3/8" tube should be cut approx 0.090" longer

at each end than the edge of the fitting it'll mate with for good fit

after flaring the end.

Found that the tubing bender I bought (Imperial 368-FH) will only do

up to 90 deg bends. Several attempts at several different

techniques to produce a 180 deg bend just didn't yield good

results. I decided to purchase another tool that's designed for

180 deg bends (Imperial 470-FH). [P.S. The 470-FH turned out to

be a better tool all around, able to do everything the 368-FH could do

and more. To my annoyance, the 368-FH cost me $41.60 and the

470-FH cost $27.60, both at Aircraft Spruce. Even more

infuriating, I later found a tubing bender that looked identical to

the 368-FH at Home Depot (apparently a generic knock off) for about

$10! @#$%! After seeing this, I went back and compared

pricing for other tubing tools. I found that Spruce was very

inconsistent on other tools as well. Sometimes they're

competitive, and sometimes they charge several times more than other

stores for the exact same item. Many of these very same tools

can be had at Home Depot or Sears for a fraction of the price.

Spruce shoppers beware!!!] |

| 2006.07.16:

(3.0) Started making my first fuel line,

from the fuel filter to the fuel pump bypass check valve (tee fitting

at the check valve also goes to fuel pump input port). The first

attempt came out nicely, except that the straight sections at the ends

weren't long enough to put on the AN819 sleeves and get the remaining

end of the tube into the flaring tool. The sleeves are approx

0.5" long and the flaring tool is approx 0.75" deep, so at

least 1.25" of straight section has to be left at each end of a

tube. |

| 2006.07.22:

(3.5) Finished making the

fuel line from the fuel filter to the fuel pump bypass valve.

Used a crow's foot perpendicular to the torque wrench to torque the

fittings.

I decided to use an Andair fuel selector valve instead of the valve

that comes standard in the kit. The decision wasn't aesthetic

(even though the Andair valve is a beautifully machined work of art,

and the standard valve from Van's looks like it belongs at the end of

a garden hose). The standard valve from Van's has a handle that

extends opposite to the selected tank, which I find objectionable from

a "human factors" standpoint. Also, there are tactile

detents in the three positions ("left", "right",

and "off") but no positive mechanism for ensuring the valve

is in the desired position. The Andair valves on the other hand

have a handle that clearly points to the selected tank. The

handle hits a positive stop at "left" and "right",

and a safety button has to be lifted to move the handle in or out of

the "off" position.

As another "human factors" improvement, I decided to mount

my fuel pump switch right above the fuel selector valve rather than in

a row of other switches on the panel. The fuel pump and fuel

selector valve are functionally related, and placing them next to each

other facilitates a natural "flow" when performing various

checklist procedures. Also, having the fuel pump switch away

from any other switches ensures that it can be operated safely by

touch without looking, with no danger of mistaking it for a different

switch. The fuel pump switch will have three positions:

"ON" (up), "AUTO" (center), and "OFF"

(down). Normally the switch will be on "AUTO", where

the fuel pump is controlled by the FADEC, except when switching fuel

tanks, emergencies, etc. An annunciator light on the panel or on

the EFIS screen will warn if the switch is in a manual override

position ("ON" or "OFF").

Owen at Andair advised me that their FS20X7T is the best choice for

the RV-7A, as it was designed to fit without too much trouble into the

existing design. As Van's now carries these, I bought one

through them. Although I'm very happy with the quality of the

valve, it seems that the choice of fittings on it could have been

better. It has all built-in fittings for flared tubing, which

leaves little flexibility. Female pipe fittings would have been

better, so that any of a number of standard AN fittings could have

been used to direct the ports before going to a tubing run. In

particular, the output port from the fuel valve needs to immediately

tee off to the fuel filter and a return from the pressure regulator

valve. Being a flared tube fitting on the Andair valve, I had to

get a female swivel fitting with the appropriate tee. This is an

AN-like fitting, but is non-standard and hard to find.

"Luckily", Van's now carries these (Van's p/n "F SWIVEL

TEE") at twenty bucks a pop. |

| 2006.07.30:

(3.0) Made two more fuel

lines. One from the fuel selector valve tee to the fuel

filter. Another from the pressure regulator valve back to the

fuel selector valve tee.

|

| 2007.??.??:

(0.0) [This entry covers

the past few weeks] Moving on to the left and right fuel lines

to the fuel selector, I found that I simply couldn't make the geometry

work. The "flared tube elbow fittings" on the Andair

FS20X7T would work great on a carbureted RV, but for a fuel-injected

RV like mine, the tubes and fittings on the Airflow Performance

high-pressure fuel pump interfere with the lines coming off the fuel

selector. A quick discussion

on the Van's Air Force (VAF) forums confirmed the diagnosis, and

the best cure others have found are the Andair BF20 "banjo

fittings" instead of the elbow fittings. Exchanged a few

emails with Owen at Andair, who also suggested the banjo fittings, and

offered to swap. |

| 2007.??.??:

(4.0) Received the Banjo

fittings from Andair, which indeed made the fuel line routing more

feasible. |

| 2007.05.18:

(4.0) Made the in-cockpit tubing for the

left fuel tank vent. First used copper wire to model the rough

shape, then bent and fitted the actual 1/4" aluminum

tubing. Note that the location for the bulkhead fitting that

goes through the side skin to the wing has still not been precisely

determined, so I left that end long for now. The location for

the fitting is not precisely shown in the plans, nor is there a

pre-punched pilot hole as stated in the plans. Since it's a

fairly tight area near the leading edge of the wing, I'll wait until I

have the wings on to determine the precise location for the fitting.

|

| 2008.05.28:

(0.0) Modified a pair of AN bulkhead

fittings to use as the fuel tank vents. Took off the thread on

one side with Vay's lathe, and also thinned out the flange some to

reduce drag. Then I cut a 45 degree angle on the bandsaw, and

cleaned it up with a file. Came out pretty nice.

|

| 2011.09.29:

(0.0) The lengths of fuel hoses

supplied with Van's firewall forward kit did not fit my particular

installation, so I returned them and instead had custom hoses made by Precision

Hose Technology, Inc. of Tulsa, OK. And since I'm having

them custom made anyway, I also used a better more modern type of

hose. Van's uses Aeroquip AE701, which is a synthetic rubber

hose with stainless steel braid jacket, and a slip-on

firesleeve. It is rated for operating pressure up to 1000 psi,

and temperature of -65° to 300° F. The hose type I selected is

Parker Stratoflex 124J. This is a teflon hose with stainless

steel braid jacket and integral firesleeve. This hose is rated

for operating pressure up to 1500 psi, and temperature of -65° to

+450° F (-54° to +232° C). And whereas synthetic rubber hose

has to be replaced every few years, teflon hose has virtually infinite

service life. It is well suited for firewall-forward fuel lines,

and is often used as such in certified aircraft.

The hose specifications I used in my installation:

Firewall to engine-driven fuel pump:

3/8" ID (-6), straight to 45° elbow, 9.0 inches long, p/n

124J003-6CR0090

Engine-driven fuel pump to fuel injection servo:

3/8" ID (-6), straight to straight, 26.5 inches long, p/n

124J001-6CR0264 |

|

|