|

Cockpit Floors and Covers

Running Total Hours:

0.0

| 2006.01.28:

(6.0) Rather than riveting the

baggage floors in place, I decided to make them removable. This

will give me relatively easy access for inspection and maintenance,

and will allow me to install equipment underneath, such as a strobe

power supply or autopilot controller. While this is a fairly

common modification among RV builders, there are different

possibilities of how to do it. Since I do consider the baggage

floors "structural", (they box in that part of the fuselage,

and therefore add rigidity), my philosophy was to make my modification

no less strong than the original. While this is certainly

overkill, I decided to replace each rivet with an 8-32 screw.

Now I'll get to work. Lots of nut plates to install. |

| 2006.01.29:

(4.0) Working on the right side

baggage floor. Installing nut plates... |

| 2006.02.03:

(3.0) When I drilled out and

removed the left side baggage floor I found a surprise. A large

countersink bit in one of the bays, left behind apparently by the QB

factory in the Philippines. That validates my idea of checking

EVERYTHING. The only other area I haven't checked thus far is

the attachment structure between the fuel tanks to the wing spars,

which would require removing the tanks. I'm now reconsidering

... maybe that would be a worthwhile exercise. |

| 2006.02.04:

(1.0) Ran out of nut

plates. Time to call Van's. |

| 2006.02.15:

(0.0) Received my order from

Van's with more nut plates and a few other items. Note for next

time: although Van's is a little cheaper than Spruce for hardware,

they take a few days to ship an order. Also, UPS ground takes a

week from Van's, whereas it's next day from Spruce. |

| 2006.02.22:

(0.5) Finished pop-riveting on

the right side seat floor. |

| 2006.02.23:

(0.5) Finished pop-riveting on

the left side seat floor. |

| 2006.02.26:

(2.0) Installing nut plates for the left

baggage floor.... |

| 2006.03.04:

(3.0) Installing nut plates for the left

baggage floor, including two "custom made" nut plates for

the joint between the floor ribs and the bulkhead. (See

description of similar custom nut plate I made: Flaps Actuator

2006.03.04)

|

| 2006.03.18:

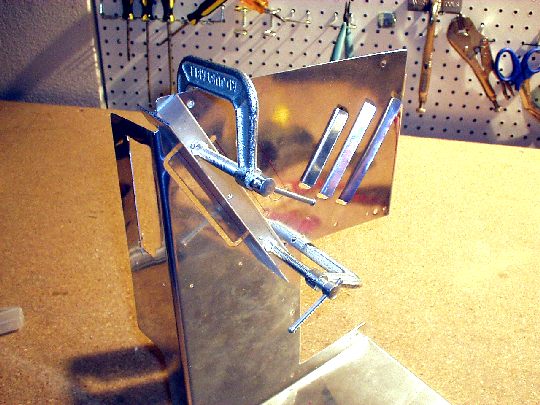

(1.5) Started fabricating the

Z-brackets for the tunnel cover. For the first attempt,

"measure twice cut once" wasn't enough. I measured

twice, very precisely, the same wrong measurement both times.

Fabricated another bracket, correct this time. But I need to

order more Z channel from Van's. I also found that the plate

Van's sent me was labeled with the correct dimensions, but in fact was

about 1/2" short. I'll just order another one too. |

| 2006.04.22:

(1.0) At the end of an AKZO spraying

session I had some left, so I edge-finished and sprayed AKZO on the

F-704K upright cap strips. |

| 2006.??.??:

(0.0) Fabricated the other Z bracket for

the tunnel cover. |

| 2006.05.20:

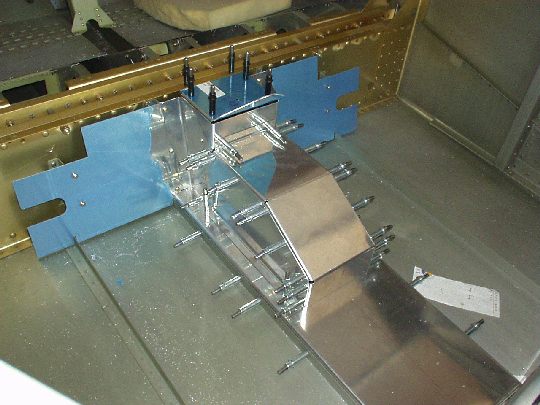

(3.0) Made the top plate for the control

rod tunnel cover. I found that the part Van's supplied was

slightly too small, and the stock design also left an unsightly gap

between the aft end of the tunnel cover and the framework for the

flaps. I fabricated my own plate from larger stock and also

added a tab at the aft end to make a nicer interface. Fitted and

drilled everything... |

| 2006.05.23:

(2.0) Since I'm planning on

a fuel-injected engine, I'll need a high-pressure (25 psi) auxiliary

fuel pump, rather than the standard low-pressure pump used for carbureted

engines. I'm using Van's kit "7/7A F.I. PUMP INSTAL"

(see section Fuel System). Unlike the standard low-pressure pump which mounts on the firewall,

the high-pressure pump mounts on the cockpit floor under the fuel

selector. This requires modifications to the structure in the

area of the fuel selector.

Started deburring parts... |

| 2006.05.24:

(2.0) More deburring... |

| 2006.05.26:

(2.5) Working on the

structure around the fuel selector and fuel pump: measuring, marking,

test fitting... no "real work". |

| 2006.05.31:

(2.0) Drilled #40 guide

holes in the floor stringers. Used a piece of angle as a drill

guide to set a hole height of 0.420". Then clamped in the

F-7115A fuel pump base plate (a.k.a. "bottom cover") and match-drilled it.

|

| 2006.06.01:

(1.0) Started modifying the

F-782C bottom cover for the high-pressure pump installation.

Shortened it to clear the F-7115A. |

| 2006.06.02:

(1.0) Continued modifying the F-782C

bottom cover for the high-pressure pump installation. Made the cutout

on the aft end. |

| 2006.06.03:

(5.0) Clamped the F-782C bottom cover to

the floor stringers and match-drilled.

Fitted and drilled the

fuel pump cover assembly.

|

| 2006.06.04:

(3.0) Prepped, modified, fitted, and

drilled the fuel selector cover. |

| 2006.06.06:

(2.5) Prepped the cabin heat baffle and

match-drilled the to the F-782C bottom cover. Bent out the louvers

on the bottom cover. |

| 2006.06.xx:

(6.0) [this entry covers several days]

Finished deburring everything, including the cabin heat louvers which

were a royal PITA.

|

| 2006.06.18:

(3.0) Finished fitting all the cover

pieces. Started drilling and countersinking for nut

plates. |

| 2006.06.24:

(2.5) Finished countersinking, and tied

up a few other loose ends on the fwd center covers. |

| 2006.06.30:

(2.5) Prepped all the front covers for

primer. |

| 2006.07.01:

(2.0) Sprayed AKZO primer on the front

covers. |

|

|