|

Flaps Actuator

Running Total Hours:

0.0

| 2006.01.15:

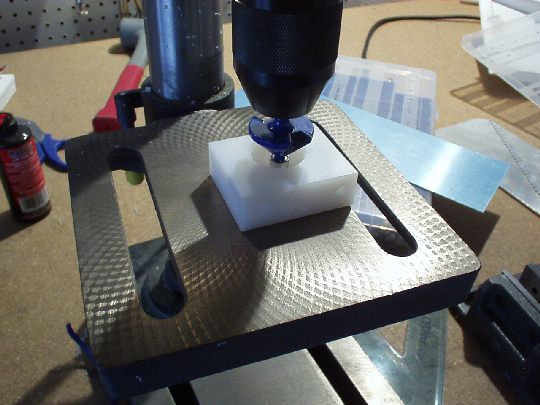

(2.0) Reamed out the bolt holes

in the torque tube weldment. Drilled the bushing blocks.

While the bushing blocks should be "match drilled" to the

pre-punched holes in the bulkhead, this is not practical as the

bulkhead is already installed. I drilled the the bushings from

measurements, which came out perfect for one and not quite for the

other. I think part of the reason was that I was just holding

the blocks down to the drill press base, and the drill tends to grab

the plastic. I'll order a replacement part and go pick up a

drill press vise. |

| 2006.01.19:

(1.0) Refer to DWG 20.

Electric flaps were an option on the RV-6(A) and are standard on the

RV-7(A). Van's design of the actuation mechanism for the

electric flaps is, in principle, simple and effective.

Unfortunately, there are a couple of serious flaws in the details of

the design that I find unacceptable. Flaws that are readily

apparent on the plans. Flaws that could have easily been

corrected, but for whatever reason were not. Annoying...

1. The motor assembly has a gearbox with a jackscrew (or similar)

mechanism used to extend or retract the actuator arm. But when I

bench tested it I found that the actuator shaft doesn't extend or

retract. It just spins. If I hold the actuator shaft to

keep it from spinning (with considerable torque), then it extends or

retracts. An query to the Yahoo group confirmed that my

actuator is not defective, that's just how it is. A good design

would have a built-in mechanism to keep it from rotating, but instead

Van's design relies on a Mickey Mouse "safety wire" through

the actuator shaft and the clevis bolt. The problem with this is

that the "safety wire" is not really a safety wire at all,

in that it relies on its overall rigidity, not just in direct tension,

to keep the actuator from spinning. Furthermore, on every cycle

of the flaps, the actuator will exert a torque on the wire in either

direction. After who knows how many cycles, the wire will work

harden, will fatigue, and eventually fail. Then the actuator

will exert a torque that will only be opposed by the jam nut on the

rod end bearing, which will eventually work loose and the rod end will

unscrew from the actuator. Not cool.

I decided to correct this by adding a retention mechanism to the

actuator itself to prevent the shaft from rotating. After

considering several design ideas, consulting with Vay, Annie, and the

Yahoo group, I decided to go with a simple design using a couple of

collars with an offset rod and a guide hole. This design concept

was used successfully by RV builder Lorne Heise, and in fact I decided

to shamelessly produce a very similar design to his. I drew up a

design, and now it's up to Annie (an ME/BE grad student and machine

shop TA) to go make me one. Thanks Annie!

2. The actuator shaft and the (weldment) torque tube arm don't line up

with each other! Conveniently, there is no single view on the

plans that shows both. But studying the plans still reveals the

problem. The motor/actuator assembly is asymmetric, with the

motor hanging to the right of center and the actuator shaft to the

left of center. The arm on the torque tube weldment though is

perfectly centered, yet the two are expected to meet up. The

"nominal" misalignment appears to be about 5/16".

Van's could have fixed this problem by simply welding the arm on the

torque tube 5/16" left of center. Why they didn't, who

knows. Presumably this is a relic from the RV-6(A) manual

flaps. But come on, retooling a welding jig is not that big a

deal, and in this case would make the design "correct" and

save a lot of trouble for us builders.

Some builders have reported "fixing" this problem by

mounting the actuator at a slight angle away from vertical.

Doing this appears to solve the problem in one (and only one) flap

position, but now the actuator and the arm will move in slightly

different planes, and therefore will try to twist the support

structure. There may be enough slop and flex in the system to

get away with this, but that's just plain kludgey.

Carefully studying the dimensions, it looks like I can compensate for

some of the misalignment in two places: 1. mount the actuator as far

to the right as it can go without causing interference, and 2. connect

the rod end bearing to the far left end of the clevis, with all the

shimming washers on the right. Looks like between those two I

can make up just over half the misalignment. Will this be enough

to get me home? |

| 2006.02.08:

(2.0) Making brackets, etc. |

| 2006.02.10:

(8.0) Working on the support

structure (did prep, prime, assembly...). |

| 2006.02.21: (1.0)

Received another bushing from Van's and drilled it using my new

Craftsman drill press vise. Came out perfect.

Interestingly, this bushing as delivered by Van's was machined to

dimensions slightly larger than nominal, and the edges have

significant burrs. The others were dead on dimensions and neatly

finished. Not really a problem, but Van's occasional sloppiness

in manufacturing/QA doesn't give me the warm fuzzies. |

| 2006.02.24: (2.0)

And on the next problem... With the bushing blocks pushed onto

the weldment as far as they go, the distance between them is

3/16" wider than it needs to be to fit the fuselage. The

tube wasn't bottoming out against the back of the bushing, but rather

the welds connecting the arms to the tube were the limiting

factor. After studying the measurements, comparing to other

builders' measurements, and consulting with Van's, it became apparent

that the basic measurements are all correct, but the welds were sloppy

and the fillets just extended too far outboard. Van's suggested

drilling the blocks off center to space them out further, but I didn't

like reducing the edge margin there. My solution (which Van's

approved) was to bevel out just enough of the bushings to make

clearance for weld fillets. I used a 45º router bit.

|

| 2006.02.25: (3.0)

With the weldment and outboard bushings now in place, I fitted the

flap actuator motor. While I was already anticipating a

misalignment (see 2006.01.19 problem 2), I now found that it's

1/8" worse because the actuator arm is welded to the tube

not quite square. Of course, it's tilted to the right, to make

the misalignment problem worse instead of better. Anyway, by

offsetting every connection as described above (2006.01.19), and

mounting the motor at a slight angle away from vertical, I got things

to fit. Despite the slight angle, actuation is reasonably

smooth. I'll have to wait until the whole structure is put

together (side covers and all) to see if there's any significant

flexing.

|

| 2006.02.26: (0.5)

Drilled the center bushing block to the floor. |

| 2006.03.03: (0.5)

Of the two holes drilled into the floor structure for the center

bushing blocks, only the aft one can be fitted with a standard nut

plate. The forward one cannot because of how the baggage floor

rib and the bulkhead overlap at the joint. I fabricated a little

plate that a nut plate can be attached to at a 45 deg angle, and is

long enough that it can be riveted to the floor rib past the lap joint

with the bulkhead. Better explained with a couple of pictures: |

| 2006.03.15: (1.5)

Drilled the cover panels to the support channels and installed nut

plates in the channels. |

| 2006.03.17: (1.0)

Cut out a clearance in the left cover panel for the bolt head.

Deburred both cover panels. |

| 2006.03.19: (2.0)

The bolts are spaced pretty far apart per the plans, which allows the

edges of the cover panels quite a bit of play between the

screws. The loose edge looks bad, and could easily get caught on

something, and could easily vibrate and make noise. So I decided

to double the number of screws attaching the cover panels to the

support channels, reducing the screw spacing from about 6" to

about 3". Drilled, installed nut plates, etc.

Note that I positioned one of the screws just above the cutout for the

bolt. This took some careful planning in precisely positioning

the screw hole, as well as the nut plate rivets, as to maintain edge

distance and not compromise the strength of the reinforcement plate on

the inside of the channel.

Ideally I would have liked to add another screw just below the cutout

for the bolt, but adding a nut plate there is likely to interfere with

the flap motor, so the one on top will have to be good enough. |

| 2006.8.20: (0.0)

I finally got around to putting together and testing my contraption

for keeping the actuator jackscrew from free-spinning. Well,

this first prototype didn't operate very smoothly. The problem

was that the aluminum rod sliding through a hole in the aluminum

collar just tended to bind and grind. I concluded that aluminum

is just too soft or produces too much friction in this kind of

interface, with that much force applied. So I came up with an

ECO ("Engineering Change Order", industry jargon for a fix

to make it work):

1. I replaced the aluminum rod with a stainless steel rod.

Stainless steel is much harder than aluminum, and tends to hold a

smoother surface.

2. On the collar side, I added a brass sleeve that will act as the

slide bushing surface instead of the aluminum. I found some

brass tube that had an outer diameter of 9/32" and wall thickness

of 0.014", yielding an inner diameter of 0.25325" (just

0.00325" greater than the 0.25" rod). I drilled out

the hole in the aluminum collar to 9/32", which actually made for

an interference fit as is. The brass tube would not slide

through it with hand force. Perfect! So I put the brass

tube in the freezer and the aluminum collar in the oven at 200ºF for

half an hour. With that temperature differential I was able to

push the tube in about a millimeter by hand, and then tapped it in the

rest of the way with a mallet. I think a couple of extra taps

with the mallet also served to compess the tube longitudenally and

expand it radially ever so slightly, for a tighter fit. In any

case, they were never coming apart again, especially after a minute

when their temperatures fully equalized. I then cut off the long

tube end and filed everything down flush, leaving a perfect

cylindrical insert. Note that I bought the brass tubing at

Marshall's Industrial Hardware, but it's also available at any hobby

shop in those displays of small metal stock. It is "K&S

Engineering stock #132".

With that ECO complete, everything operates smooth as silk. So

stainless steel against brass really does make a much better slide

bushing interface than aluminum against aluminum.

|

|

|