| 2006.04.14:

(3.5) The optional electric

aileron trim comes as another little kit that includes a Ray Allen

servo and installation materials. Unlike the elevator trim,

which uses a servo to control an aerodynamic trim tab on the elevator,

the aileron trim system provides bias using a servo that is

spring-coupled directly to the control column.

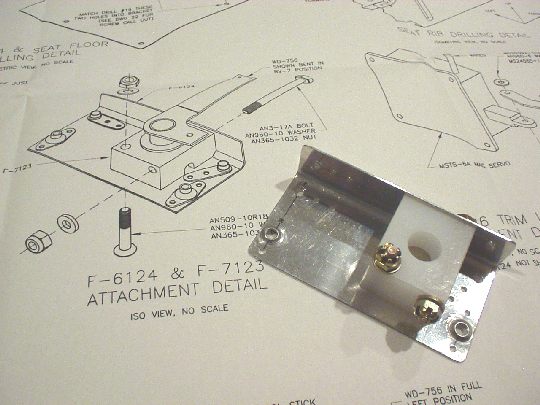

Let's get to work. Trimmed and fitted the bushing block and

bracket to each other and to the fuselage.

|

| 2006.04.15:

(2.5) Trimmed, drilled, and

bent the bell crank weldment to its final shape. Edge-finished

the little linkage pieces. Next, I ran into two design elements

that I didn't like:

1. The geometry is such that the C-606 linkages that connect the

springs to the control column will experience rotational forces (i.e.

torque) any time the stick is not centered laterally. There's nothing

to oppose the rotational forces other than the friction/tightness of

the one bolt that connects the C-606 linkage to the control column

(that also connects the F-665 pushrod). So there's potential here for

the bolt to loosen and the linkage to start rotating. Or worse, the

bolt could eventually come completely loose and the F-665 pushrod

would disconnect from the control column. Not a very robust design,

and failure here could be catastrophic. I think the simple and

logical way to do this is to redesign the C-606 linkage so that it

connects to the control column through both bolts. That way the shear

strength of the bolts opposes rotation, rather than relying on

friction/tightness. I sent an email to Van's tech support. Let's see

what they say.

2. The servo mounts to the web of the seat rib right over a protruding

bead, preventing the servo from sitting flush. There's a comment

in the plans "allow servo motor to distort bead in seat

rib". We'll see how this works out, whether or not more

than just the bead will get deformed under tension. Pretty

cheesy. |

| 2006.04.22:

(1.0) Sprayed AKZO on the trim bracket

and linkages. |

| 2006.04.23:

(0.5) Riveted the nut plates to the

trim bracket and assembled with the bushing block. |

| 2006.04.25:

(1.5) Installed the trim bracket

assembly in the fuselage and used it to position the servo motor on

the seat rib (clamped in place). I found that I didn't have any

tool that could match-drill the servo mounting holes, because of the

cramped space. The right angle drill is basically the right

solution, except that the threaded drill bits I have are too short to

clear the servo motor. Will buy some longer bits. |

| 2006.04.30:

(0.5) Match-drilled the mounting holes

for the servo using the angle drill and some 2-1/8" long bits

(#30, then #28 for 6-32 screws) from Avery. Piece of cake with

the right tools.

|

| 2008.12.10:

(0.0) Just catching up on some

documentation from a while back... With respect to the issue I

raised on 2006.04.15: As expected, Van's didn't show much

interest. That's ok. It's my airplane, so I corrected the

problem anyway.

[insert photo here] |