|

Cabin Air

Running Total Hours:

0.0

| 2007.05.17: (6.0)

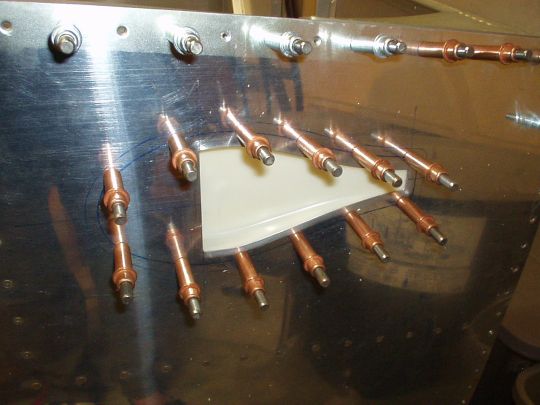

[this entry covers the past few days] The scoops themselves are molded

plastic (ABS, I'm guessing). I cleaned them up by filing down

the burrs and seams and slag. Then, located and marked their

locations on the side skins, making them fit the pre-cut holes as well

as possible. I decided to install my scoops with both adhesive

(probably fuel tank sealant) and 1/8" 120° countersunk blind

rivets (CS4-4). Located and drilled rivet holes in the skins,

then match-drilled the flanges of the plastic scoops.

Match-drilled and cut some 0.016" aluminum strips that'll go

behind the scoops' flanges. This is so the soft plastic flanges

will be sandwiched between aluminum on both sides (the side skins and

the 0.016" strips) and will not be damaged by the rivets.

Dimpled the skins and countersunk the scoops for 1/8" 120° countersunk blind

rivets (CS4-4). |

| 2008.06.26:

(0.0) The eyeball vents that

Van's ships in the kit feel like they were made by Fisher-Price.

Van's even acknowledges in the builder's manual that when closed they

still leak badly, and they advise a cheesey fix by globbing RTV around

the edges of the door... No thanks. I bought a pair of

machined aluminum vents from SteinAir, p/n AV-1.25C. These are

definitely pricey at $90 a pop, but they're definitely high quality.

These vents from SteinAir mount into a 2" round hole. They

don't have a built-in flange like the plastic ones from Van's.

So I made the flanges from 0.062" 2024-T3 aluminum. I then

mounted that in the same manner as Van's suggested mounting, but I

altered the geometry slightly, and added another screw to the

instrument panel for a more secure installation. |

| 2009.11.13:

(0.0) Trial-fitted the

ducting between the NACA scoop and the eyeball vent. This is

2" diameter ducting supplied by Van's, which appears to be

similar to CAT ducting (standard CAT/CEET/SCAT/SCEET ducting should

work just as well, but I haven't tried it). A straight duct

length of 15 inches (17 spiral rings) is about right. Note that

the ducting has to curve around the bulkhead and subpanel. In

order to secure it a little bit better and prevent vibration and

chafing, I added a nutplate to the bulkhead to secure the ducting

there with a cushioned clamp. An MS21919-34 clamp works well for

this. Note that this is a 2-1/8" diameter clamp, which

holds the 2" ducting securely without crushing it (selected

empirically by trial and error with different size clamps from 2"

to 2-1/4").

|

|

|