|

Canopy Frame and Plexiglass (Acrylic)

Running Total Hours:

0.0

| 2008.06.26:

(0.0) The canopy

frame starts with WD-716A, a fairly complicated aluminum assembly that

comes welded from Van's. Nice idea, but nothing fits. Not

sure how they jig these for welding, but there's significant twist and

mis-shapen bends in the individual pieces, innacuracies in the

relative positions of the individual pieces, pre-punched holes in

individual pieces that are therefore misaligned relative to others,

you name it. This assembly needs to mate with the C-702 skin as

well as other components, and ultimately match the contours of the

fuselage very closely at the front and sides to form a smooth

continuation of those surfaces. I've been working with this

thing for over a week now, using every trick in the arsenal to

persuade it to fit. Getting closer, but man, what a pain in the

ass! I've heard other builders complain about this, and now I

understand.

|

| 2008.07.29:

(0.0) Progress

report: Still working with this damn thing, but getting closer.

The WD-716A is now primed and riveted with the center splice plate,

and also the hinge pieces are riveted to the forward channels (with

various shims inbetween to set the right distance to the aft

tube). I'm still fine-tuning the fit of the canopy frame skin to

the forward fuselage skin by filing the WD-716A and adding shims as

needed. It's close enough now that I went ahead and drilled the

hinges. As others have experienced, the holes didn't end up

quite centered on the hinge material. So for edge distance

considerations, I decided not to use the big brass bushing inserts

from Van's, and make my own thinner ones. Whereas Van's bushings

are 3/8" outer diameter, I made mine from thin walled brass tube

with 9/32" outer diameter. That way I only had to enlarge

the holes in the frame to 9/32" (actually, I used a slightly

smaller "K" drill bit), thereby maintaining comfortable edge

distance. I easily press fit the bushings using the hand

squeezer.

To break up the monotony, I also started working on the stiffeners for

this assembly. I think this was an afterthought by Van's, first

sold as an extra sub-kit, and now part of the main kit. Anyway,

these three pieces form a truss between the bottom flanges of the

WD-716A and the skin, which should indeed stiffen up this floppy

structure considerably. The stiffeners have a total of nine

2" diameter lightening holes already cut in them, but the builder

(me) has to bend a flange along the outline of the hole for

stiffness. Van's suggests going progressively around the hole

with a bending tool, but I doubt one could get nice results that

way. I decided to make what effectively amounts to a really big

dimple dye. I made it out of 3/4" plywood, and with a

1/4" bolt in the center to provide the pressure. A picture

is worth 1000 words, so without further ado:

I was reasonably happy with the result. The flanges looked

more-or-less uniform, and they actually did stiffen up the part

considerably. For the outboard parts, the lighening holes also

had a groove on one end. For them, this "dimpling"

operation also put a little bit of curvature into the part in the

direction that it will need to curve to conform to the WD-716A.

Cool! |

| 2008.08.19:

(0.0) Progress

report: Still working with this damn thing, but getting closer.

The forward canopy frame weldment and skin are coming together nicely,

and now fit the coutours of the fuselage pretty well. It took

five rather complicated shims, and a fair amount of filing on the

weldment's flanges. The first shim is along the forward top

rivet line. It is 0.062" thick in the center, and tapers

down and bends down on the outboard ends (2 rivets outboard of the

hinges). The outboard sections of the forward rivet line are the

opposite, where material had to be removed from the weldment's flanges

so that the canopy skin will not sit higher than the forward fuselage

skin (the infamous 2 and 10 o'clock "air scoops").

There are also shims along the upper of the two longitudinal rivet

lines on each side. Rather than force the skin to pull in to the

weldment, I decided to measure the gaps through the rivet holes, and

make shims to fit. This allows the skin to follow a more natural

curvature, giving a nicer appearance and also providing better overall

stiffnes to the structure. These shims vary in thickness along

their length, and also have some twist, most noticabley at the aft

end. The are also shims along the two longitudinal rivet lines

at the top (the weldment's members that run back from the hinge

arms). These compensate for the added height due to the first

(forward) shim, and also some undesired curvature that these weldment

members took on as a result of welding. In any event, the

varying thicknesses of these shims along their lengths were also

determined by measuring depth through the rivet holes in the skin.

Now with the aft canopy decks installed again in the fuselage, I'm

starting to fit the canopy frame sides. The bottom flanges on

these parts have already been shrunk by Van's to provide some of the

necessary curvature to match the fuselage sides, but not quite

enough. I'm trying to get a hold of a shrinker to complete the

job. Hoping to find one I can borrow, and not have to buy one

just for this one job... |

| 2008.09.23:

(0.0) Progress

report: I borrowed a shrinker from Gene and it made quick work of the

side rails. Got them fitted and riveted to the forward frame

weldment.

Fitted the stiffeners to the frame. This also required some

complex shims for a good fit. I added one shim between the

center stiffener and the skin, which tapers down at the outboard ends

to match fit the flat stiffener to the curved skin. I also added

shims to fill the gaps between the weldment and the skin where the

outboard 3 rivet holes are located by the stiffeners.

Fabricated and fitted the mounting blocks for the canopy strut

attachement on the frame side. See section Canopy

Support Struts.

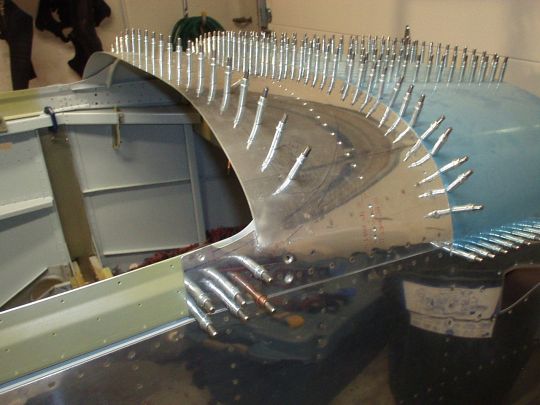

The outboard 3 rivet locations (both sides) between the skin and the

aft tube of the weldment have considerable gaps. The most

outboard rivet has a gap of approximately 0.300", the next one

approximately 0.250", and the next approximately

0.030". Furthermore, the gaps are significantly tapered, so

even a simple spacer wouldn't be a very good solution. I decided

to shim the 0.030" gap and build a little pedastal for the

0.250" gap. The outboard most location (0.300" gap) is

not conducive to any good solution I could think of, so I'll just

leave that one alone and put a dummy rivet in the prepunched hole.

(photo was taken at a later date, but shows the

various shims discussed here)

WIth all this stuff fitted, I'm contemplating the next step.

Van's would have you start fitting the plexi now, with the frame still

held together with clecos. But I'm thinking that it would be

better to rivet the frame together now so it's stiff while fitting the

plexi, and also to reduce the risk of scratching the plexi with a

cleco. This does present a couple of chicken and egg problems

having to do with the "ears" in the skin and the

"tabs" between the forward weldment and the sides. A

search on "canopy, ears" on the forum yields much

discussion... I'm currently thinking that I will remove then

ears completely, partly because they are problematic in terms of fit

and fastening, but also this will eliminate the chicken and egg

problems with riveting the skin now. With the ears eliminated,

there is adequate access to the tabs, so they can be adjusted and

rivet at a later time even with the skin already riveted on. |

| 2008.10.04:

(0.0) Progress

report: I decided after all to proceed as instructed and at least do

the initial trimming of the canopy before riveting the frame. So

the frame is still held together with clecos, for now.

Before even doing any trimming on the plexi bubble, the builder's

manual says to mark a centerline on it. Sounds simple,

but... I found that it's not quite symmetric, and there are no

good reference points. Neither the clamp marks around the edges,

nor the extra material outside the clamp marks, are uniform.

Knowing that none of these are perfect references, I located a series

of center points based on each set of possible references, which

varied by as much as a half inch. I used a taught string from

front to back to make the line more or less straight, and ran it down

the "average" (eyeballed) of the center points I

marked. As best as I can tell, the accuracy of this centerline

isn't actually important. The only way I see it being used in

the manual is to keep the forward and aft canopy pieces in proper

alignment after they've been separated. I suppose this marked

centerline could also help in aligning the canopy on the fuse, but

really I think that fit rather than this sloppily marked centerline

will be determine final alignment.

On to cutting. The manual instructs to initially just cut off

the clamp areas on the sides and aft, and the extra flange in the

front. Sounds reasonable, but again there are no really good

references, so it takes some good eyeball work. Not knowing how

much extra material there is in the molded canopy, I was a little

nervous about cutting off too much. [But fast forward a couple

of days, all turned out well.] I did the sides first, making the

cuts about 1/4" in from the clamp marks, where the plexi is again

"clean" -- free of distortions and texture. I then did

the back, same idea. Lastly I did the front, which is

different. As it comes from the mold, the front of the canopy

has a substantial "flange" area, which actually closely

mimics the shape of the forward canopy frame skin. The

transition between this flange and the usable part of the canopy is

well defined around the center with about a 1/2" radius bend,

gradually becoming smoother and less defined outboard. I made my

cut such as to completely eliminate the transition area, which was

very clear in the center, and again used some artistic eyeball to

conservatively extend the curved cut outboard, where the transition

was no longer distinct.

Various tools and techniques for cutting and dressing the plexi have

been widely discussed on the forums. I also paid a visit to Ridout

Plastics, a local plastics shop (with online store as well), to

buy some tools and ask for any advice they might have to offer.

On the advice side, they were definitely very knowledgeable about

working with acrylic (a.k.a. "plexi"), and were happy to

chat about it. Their advice about cleaning up edges after

cutting was similar to that used by many builders -- a scraper tool,

and sand paper. On the cut itself, they suggested a hand-held

jig saw. To me that seems like asking for trouble because of the

reciprocating action and lack of support to the oddly shaped

canopy. I decided to first try Van's tried and true method using

a cutting disc in a die grinder. In any case, I also picked up

some scrap pieces of acrylic at Ridout so I could experiment and

practice on before doing the real thing. The die grinder worked

ok, but not great. Its low torque would tend to get it stuck,

and also necessitated running it at higher RPMs than I would like,

making it hard to control. Using Van's cutting disc in the

pneumatic drill worked out much better. Its high low end torque

made for much better controllability, especially for the first

pass. To summarize, either the die grinder or the drill can do

the job, but the drill is more controllable and ultimately leaves a

cleaner cut. BTW, whether I used the die grinder or the drill, I

didn't make the cut in one pass. I took about 5 or 6 passes to

cut all the way through the material. My technique was to first

mark the cut line by putting down blue masking tape. I put 3

layers of masking tape to give it enough thickness that it would

actually guide the tool back somewhat if I strayed too close to the

line. I then did a very slow and careful initial pass, using low

RPMs, to cut a shallow groove that will henceforth be the guide.

I then made additional passes with increasing RPM and pressure to

progressively deepen the groove, until the final pass cutting all the

way through. After the cut is made, the edge has to be smoothed

out. I found that the best way to do it is with a sanding

block. First with 60 or 80 grit, moving to 150 grit, and finally

400 grit. Then, chamfer the corners with the scraper tool.

Note that the side of the scraper tool without the grooves can also be

used to work down the edge, but I found that sandpaper works

better. The cutting operation can leave little burrs, and the

scraper would have a tendency to catch on these, whereas sand paper

does not. Note that all work on acrylic should be done at warm

temperatures (75° to 80° F is good). We've had some hot days

recently, which worked out perfectly. And otherwise I use a

1500W space heater to warm up the garage when necessary.

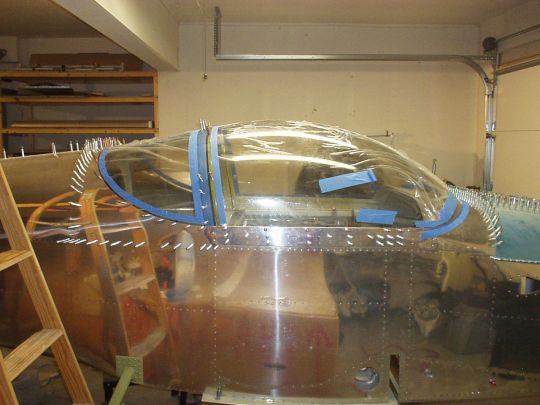

So after the initial trim, today I laid the plexi on the airplane for

the first time. Looks cool! To my surprise, it actually

fits pretty well (that's a first with anything related to the

canopy). Around the front there are some gaps of no more than

about 1/8" where it doesn't fit the contour of the canopy frame

quite right, but that should be easily fixed with another couple of

minor trims to the bubble. Above the roll bar there's only about

a 1/4" gap, which is better than most from what I've heard.

At the aft end there's about 2" of extra material, and about

0.5" along the sides. So I have to say, so far so good.

|

| 2008.10.17:

(0.0) Progress

report: Several rounds of incremental trimming around the front of the

canopy, and it is now fitting the contour of the skin reasonably

well. It's not perfect yet, but I it will also change somewhat

after the big cut, with the canopy acutally resting on the cabin

frame, and also with the sides pulled in all the way to the side

rails, so good enough for now.

|

| 2008.10.19:

(0.0) Progress

report: I made "the big cut", splitting the canopy into two

at the center of the cabin frame. It was a delicate job, but by

taking it slow and careful (over an hour just to cut an initial

groove), the results were about as good as one could hope for.

Nice clean straight perpendicular cuts with no major material removal

required to finish the edge. A couple of hours of sanding later,

and this milestone is now behind me. Now, to continue fitting

the forward canopy...

|

| 2008.12.02:

(0.0) Progress

report: I was away on vacation for 3 weeks, but still since the last

log entry there's plenty to report. Progress is being made on

several fronts.

"Tabs": I've finished trimming the bottom (i.e. front and sides) of the

forward half of the canopy, and have adjusted and riveted the

"tabs" which connect the forward frame to the side

rails. This was a very iterative process, and the results are

not perfect but pretty good. The fit in the area with the

"tabs" and the "ears" still leaves some to be

desired, but at this point, the tabs and the frame's inner structure

are no longer the limiting factor. It's the contour of the

canopy vs. the contour of the outer skin of the canopy frame around

the "ears" is now the issue. It's not the ears

themselves that are the problem, but rather the fact the the

glareshield skin just forward of the ears does not provide any room

for the canopy bubble to transition through. A bit hard to

describe, but I'll add a picture that should clarify the

situation. Back to the problem, I could see two possible

solutions: 1) notch out more of the glareshield skin forward of the

ears, as some builders have done, or 2) bend a notch into the skin

without removing any material. It seemed to me that enlarging

the notch forward would significantly weaken the structure, or at

least make it lose some rigidity, so I opted for option 2. I

used a 1/4" steel rod to push in the skin and create a channel

for the bottom of the canopy to ride in. Again, this took some

trial and error, but ultimately the results were satisfactory.

"Ears": I've also been deferring the decision on what to do

with the "ears", and now as I'm getting ready to rivet the

canopy frame skin on, it's decision time. The goals are to

ensure that the canopy glass is robustly held in position (it wants to

bow out), and to achieve a nice fit and finish. The deficiencies

in Van's design are that the ears don't naturally conform very well to

the canopy bubble, and that there are no fasteners or any other means

to secure the ears to the canopy glass. Forward of the ears a

fiberglass fairing will be formed in place, which will also blend over

the ears, but I want to make sure that the fiberglass and the aluminum

ears work together and not against each other... Again, hard to

describe, a picture should help. Anyway, my solution was to add

a screw through the aft end of the ear, sandwiching the canopy glass

between the ear and the frame just like along the side rails. So

this secures the aft end of the ear. And then forward of that, I

trimmed the ear down to about only 1/4" above the bottom of the

canopy. This will provide support for the canopy glass and keep

it from bowing out, but will ultimately be fully covered by

fiberglass. Since the forward part of the ear is cut that low,

the fiberglass fairing will be extended back over this area, and will

reach higher up than the aluminum on the canopy bubble, with the

fiberglass forming the final lines.

Lights: I decided to install an LED light strip under the glareshield

to provide panel lighting (and possibly cabin lighting, if I find it

sufficient). See Cockpit Lighting. |

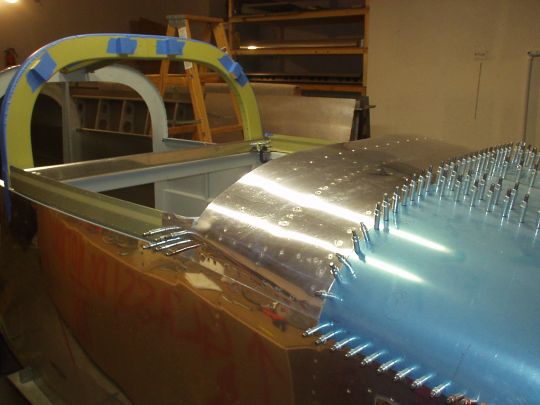

| 2008.12.08:

(0.0) Progress

report: The canopy frame is primed, partially painted, and I've

riveted on the forward skin with Jimmy's help. So far its

holding its shape quite nicely. I've been doing everything as

much as possible with the canopy frame all clecoed together and

clamped down to the fuselage. I think that helped. I'm now

riveting on the stiffener kit. |

| 2008.12.11:

(0.0) Riveted the stiffeners to the

forward canopy frame. I was able to do the right side on my own,

with gun in right hand and bucking bar in left hand. But the

opposite feels too awkward, so Greg Larson came over and helped me do

the left side.

|

| 2008.12.15:

(0.0) Progress report: Final-fitted and

riveted the rear bow to the canopy frame.

Also, contrary to Van's recommended sequence, I went ahead and fitted

the side skins now, before the plexi is drilled. My reasoning is

that for drilling the plexi, the side skins can be clecoed in place to

provide the ideal "clamp" for holding the plexi in place,

and also serving as a drill guide. There is, as Van's notes,

quite a bit of flex in the side rails, so they will probably move

around some when pulled tight to the plexi. But that's an even

better reason to use them to hold everything in its final position

when drilling the plexi. And worst case if it does significantly

change the fit of the side skins, I can then always fabricate a new

set if necessary.

|

| 2008.12.18:

(0.0) With everything clamped in place,

I marked the hole pattern for the rear canopy along the rollbar, and

the hole pattern for the forward canopy along the aft bow of the

canopy frame. I ended up using approximatly 2.25" spacing

(Van's recommends 2.5") to avoid edge distance problems with the

rivets in the canopy frame. I also started experimenting with

drilling on some scrap pieces of plexi. Doesn't seem too

bad. So I'm just about ready to start drilling the real thing,

but I have a temperature problem. Yes, it gets cold in winter

even in San Diego. Yes, cold is relative, but this 60° F

weather we've been having is too cold for my liking, and too cold for

safely working with plexi. I'd feel safer with 75° F.

Well, I ran my little 1500 W space heater for over an hour, and it

only got the garage up to about 65° F. I'll have to find a

heater with a little more UMPH! I don't think I want to wait

until summer to drill the canopy. |

| 2009.01.05:

(0.0) Progress report:

The weather isn't getting warmer any time soon, and I'm just not that

patient, so I went out and bought a second 1500 W heater. With a

total of 3 KW going, I was able to heat the garage to 75° F, and hold

it pretty accurately with the thermostats. I'm not looking

forward to the electric bill, but oh well. To keep things

precise, I'll will try to do all the plexi final fitting and drilling

as close as possible to 75° F.

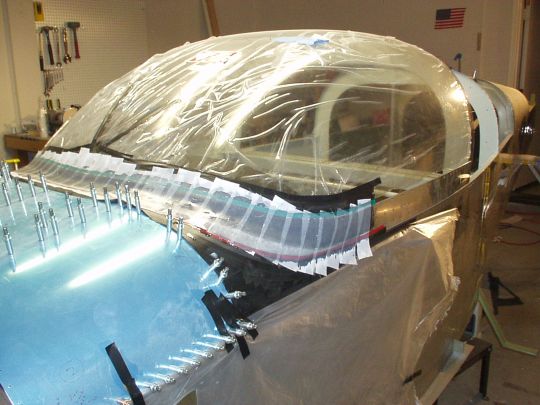

On to the drilling. I clamped the canopy frame to the fuselage

and positioned the plexi on it. I clecoed on the canopy frame

side skins, which nicely sandwiched the sides of the plexi in

place. I used duct tape to pull the plexi down into position all

around the sides, front, and back.

I then match-drilled the sides using the holes in the side skins as a

guide. Note that I did this using a 1/8" plexi drill bit,

even though I was drilling through a sandwich of aluminum - plexi -

aluminum. Since both pieces of aluminum were already pilot

drilled to 3/32", the plexi bit only had to enlarge those holes

to 1/8", which it did without too much difficulty. After

drilling each hole to 1/8", I then also ran a #30 reamer through

it, which produced immaculately clean holes, and also prepared the

canopy to eventually be countersunk using a bit with a #30

pilot. (I also deburred the holes using a permagrit countersink

bit once the plexi was removed from the frame.)

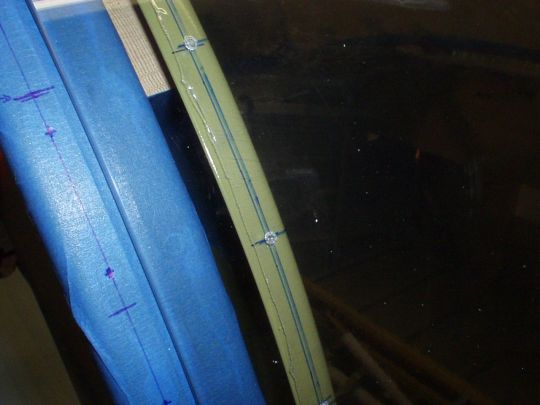

With the sides drilled and clecoed, I moved on to the aft edge (i.e.

the arch that matches the rollbar). These, I did not drill in

place. I transferred the hole pattern that I marked on the

canopy frame arch onto the canopy, just in sharpie on the protective

plastic, so that I could double check the straightness and evenness of

the hole pattern. I then only pilot drilled less than half way

through the plexi, just to set the hole locations. [Note: In the

photo it looks like the holes are messy with big burrs, but that's

just the protective plastic. The holes in the plexi are actually

very clean with no discernable burr.]

I then removed the plexi and drilled the holes through it on the bench

(1/8" plexi drill bit, #30 reamer, permagrit countersink for

deburr). When drilling the plexi I clamped another piece of

scrap plexi with matching curvature to the inside as backing material,

to prevent the bit from punching through or chipping the back of the

hole.

I then put the plexi back in position on the canopy frame, of course

clecoing all around the sides, and match-drilled the aft arch using

the holes I just drilled in the plexi as guides. I drilled the

frame using a standard (i.e. non-plexi) 1/8" drill bit, and then

ran the #30 reamer through the plexi and frame again. Great

results.

I have only two more holes to drill through the plexi of the forward

canopy (there's always something...). Recall that the

forward-most hole on each side is one that I added that goes through

the forward skin, not the side skins. And I had to already

enlarge and dimple the hole in the skin for the #6 screw before I

riveted on the skin. I wisely left the opposite hole through the

inner side rail at 3/32". But this does mean that I have to

match-drill this one from the inside rather than from the

outside. So I'll do this at the next convenient opportunity.

I also started fitting the rear window. I can see this is going

to be a real PITA, because the top of the rear window plexi is

substantially concave along the fore-aft axis (what Van's calls a

"duck tail"?), which causes it to press against the

structure between the roll bar at the front and the bulkhead at the

back. The plexi will be under stress, and will not interface

with the skin nicely in the same plane. Damn it... I

anticipate this being another one of these "massaging"

situations. In the mean time though, I prepared the top skin,

chamfered its edges, and marked and pilot-drilled a hole pattern for

the screws that will connect the plexi. I also took this

opportunity to correct the angles of the flanges in the bulkheads that

mate up with this skin. The QB factory over-bent these by a good

30 degrees. |

| 2009.01.14:

(0.0) Progress report:

Working on the rear window. Despite the concavity issue, the fit

has actually turned out pretty descent, with the plexi pulled down to

the roll bar with only a moderate amount of force -- not enough to

cause any problems.

I drilled the rear window starting in the aft center, working outwards

left and right while the forward edge of the window is clamped down to

the roll bar, and Stacey pushing the window from the inside tightly

against the fuselage skin. About the photo: after 5 attempts I

gave up on getting a photo with her eyes open, oh well.

I then drilled the holes along the front edge of the rear window in a

similar fashion as I did the aft edge of the forward canopy. I

first transferred the hole locations to the plexi (covered with

transparent celotape) with sharpie pen, and then I drilled. But

unlike the aft edge of the forward canopy, this time I went ahead and

drilled the plexi while still in assembly on the fuselage, all the way

until the drill bit hit the roll bar. The holes in the roll bar

will ultimately be drilled and tapped for 6-32 screws, so that's a

smaller hole than 1/8". Letting the 1/8" plexi bit

just hit the roll bar will later help as a center guide for drilling

through the roll bar. I removed the plexi from the fuselage and

finished drilling the holes all the way through the plexi, and then

reaming them to #30. I then clecoed and clamped the rear window

back to the fuselage, and drilled through the roll bar to 1/16"

(which will serve as pilot holes for the #36 drill prior to

tapping). I chose to have the plexi on the fuselage for this

operation only in order to help drill the holes at the right angle,

perpendicular to the surface of the plexi, which is not exactly the

same as the roll bar. Anyway, it is also much easier to sight

the angle with the plexi in place, because I can clearly see the

reflection of the drill bit. Anyway, that's done. But then

I discovered that I don't have a #36 drill bit, so that'll have to

wait.

The forward edge of the rear window matches nicely to the roll bar

center line, with only a couple of high spots that still need a bit of

sanding. I marked these with masking tape and will take care of

them at the next convenient opportunity.

My next major task for the rear window will be to make the

"optional" backing strips shown on the plans. I think

this is a good idea, as it will help spread the load from the

fasteners more evenly across the edge of the plexi. It will also

make for a nicer looking finish on the inside.

Today I also drilled the two remaining holes through the forward

canopy. Just clecoed the plexi back to the frame, and drilled

through from the inside. I still need to trim the aft edge, and

will probably do so in the next few days. I also marked with

masking tape the line where the canopy meets the glare shield. I

plan to paint the glare shield (the portion inside the canopy) flat

black.

|

| 2009.01.24:

(0.0) Progress report:

Fabricated 0.025" aluminum backing strips for the rear

window. Came out nice.

Did a couple of last iterations of final fitting (sanding only, no

cutting) to get the gap between the forward canopy and the rear window

to an even 1/32". Now with everything clecoed in place, the

canopy opens and closes with no interference. Looks sweet!

The fit between the forward canopy and the rear window is almost

perfect along the top of the roll bar, but not so great on the

sides. Basically, the rear window sticks out further than the

canopy, presenting a "step" to the airstream. A

careful examination of the airframe's geometry makes it clear why this

is the case. At the roll bar, the fuselage is tapering back,

becoming narrower as you go aft. The plexiglass canopy also has

a similar contour. The roll bar however is simply square, it

doesn't match this taper. As a result, the plexiglass and the

outside of the roll bar are not exactly in the same plane. Now,

the forward canopy has been fitted to mate neatly against the

centerline of the roll bar all the way around. So only the very

aft edge of the forward canopy plexi actually contacts the roll bar

near its centerline, and the plexi sits a little higher (i.e. not

making contact) at the very forward edge of the roll bar. In the case

of the rear window, the mismatch is in the opposite direction, such

that the window plexi only contacts the very aft edge of the roll bar,

and the very forward edge of the window sits a little bit higher (i.e.

not making contact) at the centerline of the roll bar. Hence the

mismatch at the roll bar centerline. Again, along the top this

is alost indiscernible. But on the sides the mismatch peaks at

about 0.040", quite noticeable to me and to the airstream

(drag!!!). We'll I've been debating anyway for some time whether

or not to make a targa strip. Now it looks like I pretty much

have to.

Started experimenting with various tools and techniques for

countersinking the plexi (using scrap for now). I haven't gotten

a result I've been really happy with yet, so this effort will

continue. |

| 2009.02.16:

(0.0) Progress report:

The plexi (canopy and rear window) is countersunk and drilled to final

size.

I experimented with several methods (on scrap) for countersinking

suggested by other builders, and some worked better than others.

First attempt: The permagrit countersink bit gave surprisingly rough

results. The grit was just too coarse. Second attempt: My

standard 3-flute machine countersink bit in a cage first gave mixed

results. It was difficult to start, required a scary amount of

pressure, and left a mostly smooth cut except for some subtle

rings. Third attempt: I had a hunch that the problems with the

3-flute cutter may simply have to do with it being well used and not

so sharp anymore. I bought a new cutter, which worked much

better. It took less pressure, although still quite a bit, but

cut consistently and left a totally smooth countersink. I did

the real thing using this technique.

After countersinking, I still had to enlarge the hole to its final

size. This was relatively easy, with several good options.

Just running a 5/32" plexi bit through it does the job pretty

well. Being extra cautious, I thought I would also follow that

up with a #22 reamer, to leave an even cleaner hole. That also

worked well. But it turned out that I could skip the 5/32"

drill, and use the #22 reamer directly on the existing #30

holes. That's how did it.

After doing this I did a final fit check, and ended up trimming just a

tad more from the left side bottom edge of the canopy to make sure it

doesn't interfere with the joggle in the side rail. Hopefully,

that's the last plexi trimming I will ever have to do! ;-)

With everything trimmed and fitted, it was time to button up the

canopy frame. I final drilled/reamed and countersunk the side

rails and skins, and riveted on the skins. Also made an external

lifting handle on the pilot side. Another fit check after

riveting and everything looked pretty good. I had to trim the

bottom edges of the side skins a touch more, and everything was

perfect again. And I was pleasantly surprised at how easy it was

to insert and remove the plexi despite the dimpled screw holes in the

side skins.

I decided to attach a pair of spacers below the aft ends of the canopy

side rails that would sit against the fuselage canopy deck when the

canopy is closed. That way, the vertical position of the canopy

is limited by the metal frame rather than the aft edge of the

plexi. I carefully adjusted the thickness of the spacers

(1/8" main spacer, plus thin adjustment shims), trimmed the

canopy latch cams ("fingers") a smidge, and in doing so got

the thing to sit solidly when closed, and let the latch handle operate

smoothly without excessive stress/strain during the over-center

transition.

Gave a coat of gray paint to the remaining interior surface of the

canopy frame, except for the top surface of the glare shield, which

will get a coat of black paint.

Another little refinement done on many tip-ups, I create a funnel-like

guide along the roll bar that lines up the canopy laterally as it

closes. The canopy structure is still pretty flexible, and this

mod helps prevent careless bumps and snags that could damage the

canopy if closed while out of alignment. Note that it is still

possible with extreme twisting of the canopy frame to miss the funnel

guide completely. And in any case, the canopy should always be

closed carefully and gently, so it doesn't just slam down. It is

not nearly as foolproof as, say, a car door. |

| 2009.02.22:

(0.0) Progress report:

I bought a "deluxe glare shield trim" piece from Classic

Aero Designs. This provides a padded covering for the glare

shield edge, which is a good safety feature. It also hangs down

about 3/8" below the glare shield edge, which will help hide the

light strip from direct line of sight. Hiding the light strip is

not for aesthetics, but rather to prevent looking directly at the

light source and ruining night vision. On aesthetics though,

this trim piece is nicely upholstered in a black synthetic leather and

looks very nice.

I fitted the trim piece to the glareshield, which merely involves

locating some screw holes. I then painted the top of the glare

shield flat black (Krylon Fusion 2519 Flat Black). And once that

dried, I installed the LED strip on the bottom of the glare shield. |

| 2009.02.25:

(0.0) A big day (or actually, a long

night). I attached the plexi bubble to the canopy frame for

good. Difficulty-wise, this would have been a non-event, except

that I decided to use fuel tank sealant (a.k.a. "pro-seal")

to seal the interface between the plexi and the side skins. That

stuff is a nasty, sticky, goopy, stinky compound with a limited

working time, and is very tenacious once cured. So I had one

chance to get it right. And I did. Whew.

Some other details to note. Rather than the nylock nuts called

out on the plans, I decided to use acorn nuts. This is motivated

by my goal to not have any sharp protrusions in the cockpit (the sharp

protrusions being the end of the screw coming through a nylock

nut). Since the acorn nuts don't have locking nylon inserts, I

used a dab of thread locking compound (Loctite ???). I did this

VERY CAREFULLY so it never comes in contact with the plexi. To

reduce glare I also painted the acorn nuts and washers with my

standard interior paint. I did this about a week prior to the

installation. With the hardware pre-painted before assembly, I

don't have to worry about painting anywhere near the plexi.

Man, it's nice to have this step behind me. I'll take a moment

to admire it before getting back to work :-).

|

| 2009.03.06:

(0.0) Quick update: I'm getting ready

to do the composite fairing around the forward edge of thre

canopy. Before I do though, I'm going to get my hands dirty with

some less ambitious composite work on the wing tips and empennage

tips. Just to gain experience and confidence working with

composites, and lessen the probability of making a high-stakes mistake

on the canopy. Stay tuned. |

| 2009.03.09:

(0.0) Did a bit of composite work on

the wing tips, and that went pretty well. So back to the

canopy. I started by creating a structural (flox) fillet all the

way around the front, trying to basically continue the contour of the

outer surface of the plexi all the way down to the aluminum

skin. Came out pretty good. But I think I'll do one more

pass to fill in some low spots before doing the layups. My goal

here is for the layups to have a continuous surface with a uniform

contour to lay on. I don't expect this to be perfect and it will

not be the final finished surface. Non-structural fairing filler

(i.e. "micro") over the layups will serve that

purpose. But having the layups conforming to even gentle

contours should provide maximum strength, as well as a good foundation

for the subsequent fairing filler.

Note in the photo that the flox fillet is gray, not white. This

is due to black pigment that I added to the mix. I will do the

same with the layups. The idea is to keep the cockpit interior

color-neutral so it's not visually distracting, and to minimize glare.

Note also the red electrical tape in the photo. This masks off

my planned boundaries for the fiberglass fairing. The top

boundary is approx 5/8" from the edge of the plexi all the way

around, and approx 1" from the aluminum skin in the front and a

bit more around the sides due to the fillet angle. Van's drawing

shows 1" overlap of the plexi proper (i.e. excluding the fillet),

but I believe that 5/8" should be sufficient structurally in this

application. The reduced overlap makes the fairing match the

side skins better aesthetically, and also is less obtrusive to the

pilot's forward visibility from the cockpit. I have a STRONG

preference for cockpits that give a good high view over the

cowl. The RV-7A is actually not stellar in that regard, but I'll

do what I can to that end.

P.S. one more note about surface prep. 1. Clean with VM&P naphtha (what is "VM&P"???). This is one of the

few solvents that is reportedly safe to use on plexi. 2. Abrade

with red scotch brite pads. 3. Another pass with naphtha.

|

| 2009.03.16:

(0.0) Did several more rounds of

fill & sand on the flox fillet, and it is finally a beautifully

contoured work of art! Around the front it's basically a

continuation of the plexi's contour, plus a radiused transition to the

aluminum. The areas around the sides were a bit more tricky,

where the continuation of the plexi's contour would actually end up

never intersecting the aluminum skin. So here I just used an

artistic eye to blend the contours. I also blended a bit of flox

around the aluminum "ears", so that the fiberglass will have

a continuous surface to conform to. |

| 2009.03.19:

(0.0) Laid up fiberglass around

the front of the canopy. Following the advice of Dan Horton

(composites guru on VAF forums), I ended up doing this using the

pre-preg sandwich method, three plies of RA7781 all at once, a

full-length strip reaching all the way around. John Nichols came

over to help me with this, which was a good thing. With the two

of us, this was a difficult, messy, aweful task. By myself this

would have been impossible. The results were decent.

Inevitable there are some small voids that need feeling, and lots of

blending (fill, sand, repeat) that I have to look forward to.

But that's how this goes.

I also added black pigment to the epoxy, which had mixed

results. I added enough to make the epoxy appear pitch black in

the mixing cup. But when I used it to saturate the cloth, it

became apparent that much more would have been needed to really do the

job. The wet cloth was a bit darker in appearance than normal,

but still quite transparent. Now that it's cured, it looks dark

gray from the outside, but not very dark at all from inside the

canopy. The fiberglass is still quite transparent when

back-lit. We'll see how it does once its exterior is primed and

painted. Anyway, however it is, I'll have to live with it at

this point.

As a side note, I am now soooooo happy that I built a (mostly) metal

airplane! I couldn't imagine doing nothing but this nasty

composites work for several years!

|

| 2009.04.16:

(0.0) Sanding...

|

|

|